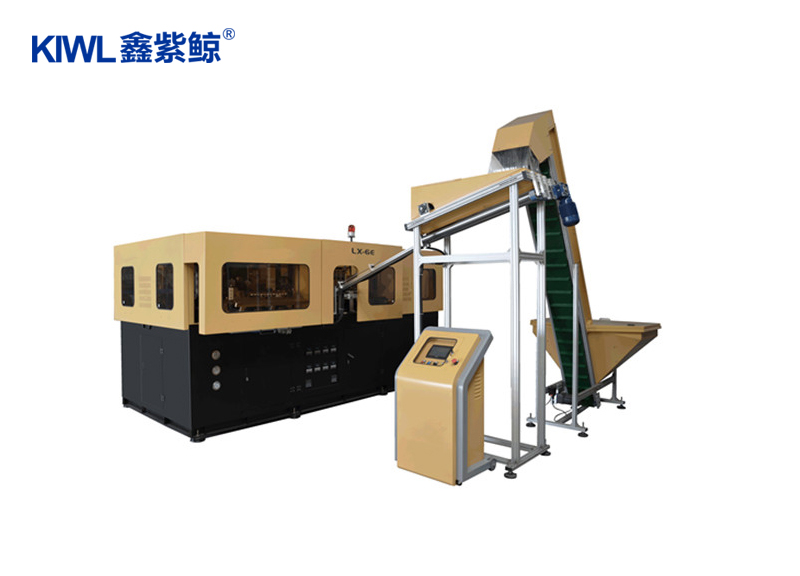

The automatic barreled water production line is a special equipment for filling 3 gallons and 5 gallons of pure water, and can also be used for filling distilled water, mineral water and other sterile liquids The equipment integrates automatic capping

The automatic barreled water production line is a special equipment for filling 3 gallons and 5 gallons of pure water, and can also be used for filling distilled water, mineral water and other sterile liquids.

The equipment integrates automatic capping, automatic external brushing barrel, automatic bottle loading mechanism, automatic bottle washing and disinfection, automatic filling, automatic capping, automatic capping and light inspection, heat shrinkable film, bucket bagging, and finished product delivery. The raw materials used meet the requirements of the food industry and other industries. The equipment adopts AC380V power supply

Pneumatic components: adopt Taiwan Yadeke, and electrical components adopt Japan Mitsubishi. The system has reliable performance, simple operation and simple maintenance. Whole bottle washing, filling

The whole process of capping and capping is carried out in the closed tunnel, which effectively prevents the secondary pollution that may occur during the filling process of purified water, and fully complies with the sanitary standards.

The machine body is made of high-quality stainless steel, and other parts are made of non-toxic and durable composite materials. The electrical and pneumatic systems are made of imported components, so the equipment failure rate is low and the reliability is high.

Working steps: automatic capping - automatic external brushing - automatic barrel loading - medicine washing - internal and external washing of raw water - internal washing of pure water - filling - automatic capping - capping - automatic conveyor belt outgoing - lamp inspection - heat shrinking - finished product