The batching system is a fully automatic batching equipment commonly used in the food, pharmaceutical, chemical and other industries to mix and prepare various materials in proportion The system adopts a fully automatic PLC control system to control the

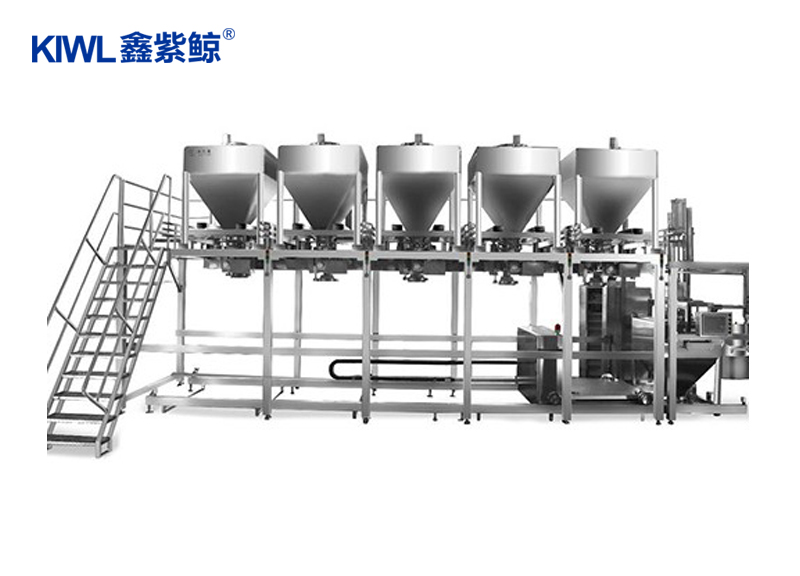

The batching system is a fully automatic batching equipment commonly used in the food, pharmaceutical, chemical and other industries to mix and prepare various materials in proportion. The system adopts a fully automatic PLC control system to control the processing control valve and the parameters such as the detection temperature, pressure, PH value, etc. to realize the full automatic control of the batching process. It has the functions of automatic heating, temperature control, heat preservation, mixing, etc., with fast heat transfer, large temperature difference adaptation, and convenient cleaning.

The batching system is a fully automatic batching equipment commonly used in the food, pharmaceutical, chemical and other industries to mix and prepare various materials in proportion. The system adopts a fully automatic PLC control system to control the processing control valve and the parameters such as the detection temperature, pressure, PH value, etc. to realize the full automatic control of the batching process. It has the functions of automatic heating, temperature control, heat preservation, mixing, etc., with fast heat transfer, large temperature difference adaptation, and convenient cleaning. 1、 Overview of batching system

The batching system is a fully automatic batching equipment commonly used in the food, pharmaceutical, chemical and other industries to mix and prepare various materials in proportion. The system adopts a fully automatic PLC control system to control the processing control valve and the parameters such as the detection temperature, pressure, PH value, etc. to realize the full automatic control of the batching process. It has the functions of automatic heating, temperature control, heat preservation, mixing, etc., with fast heat transfer, large temperature difference adaptation, and convenient cleaning.

2、 Composition of batching system

The system covers such links as raw material feeding and transportation, raw material storage, formula selection, automatic batching, material transportation, mixing and mixing, finished product discharging, etc. It is mainly composed of batching tank, mixing tank, PLC fully automatic control system, mixing device, heating device, mechanical sealing device, condenser, cooler, jacket or coil, transmission device, shaft sealing device, thermal insulation medium, inlet (outlet), support, CIP interface components, etc.

The main equipment of the batching system is made of SUS304/316L high-grade stainless steel, which has good corrosion resistance, high temperature resistance and other characteristics; The inner cylinder wall adopts mechanical polishing or electrolytic mirror polishing, the outer cylinder wall adopts 304 all-welded structure for thermal insulation, and the outer surface adopts mirror or matt treatment; The external connection of the cylinder adopts sanitary quick-opening joint, mechanical seal or flange seal, with strong sealing, safe and sanitary without dead angle, reducing the probability of material pollution, and meeting the national GMP sanitary standards.

The online control system of the whole batching system adopts color LCD touch screen+PLC full-automatic control, which can detect and control the relevant parameters of material preparation and mixing process online. The control system includes sterilization interface, parameter setting and correction, data curve, data report, batch number setting, online animation, alarm device, etc. It can be connected to the upper computer, computer and printer to realize remote monitoring, data storage and printing, with high accuracy of parameter setting and reduce material waste.

The batching system is generally equipped with temperature control device, temperature measuring hole, CIP automatic rotary spray ball, defoamer, baffle, air distributor, temperature sensor, mirror spotlight, liquid level gauge, weighing and metering device and other equipment, which is convenient for manual operation, simple and reliable.

3、 Structural characteristics of batching system

1. The main equipment of the whole batching system is made of SUS304/316L high grade stainless steel, which is polished inside and outside to prevent materials from sticking to the wall and easy to clean;

2. All process openings such as entrances and exits, mirrors, manholes, and the welding points of the tank body adopt the stretch flanging process arc transition, which is smooth and clean without dead corners, to ensure the reliability and stability of the production process;

3. The batching system can realize simultaneous metering and continuous batching at multiple stations, with high production efficiency and accurate batching;

4. The online PLC full-automatic control system of the batching system has a full Chinese interface, with rich operating tips, convenient and fast operation, and can realize the full-automatic control of the batching process and automatically detect the operation; Realize online CIP cleaning, clean and sanitary, and ensure that materials are not contaminated;

5. The weighing control instrument of the system adopts international imported equipment, with high accuracy, strong anti-interference ability, safety and reliability;

6. Low energy consumption design ensures more energy saving in the production process, optimizes the dust removal and recovery system, and is equipped with a stand-alone filter to ensure no dust entry, reduce the probability of material pollution, reduce the waste of raw materials, and achieve high-precision batching.