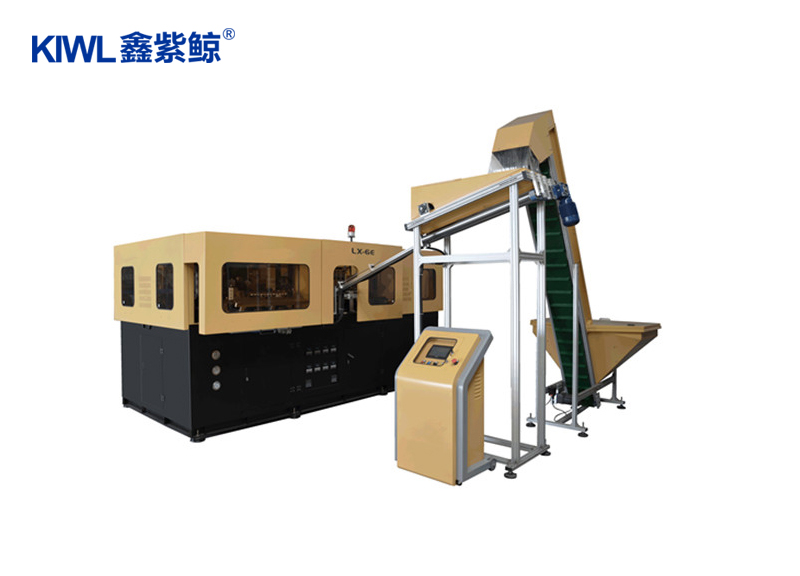

One out four blow bottle machine

-

category

-

model number

-

specs

instructions

Core advantage:

Efficient production: The unique four-mold cavity design, compared with the traditional single or double cavity blowing machine, the production efficiency is significantly improved, to meet the needs of large-scale production, shorten the delivery cycle.

Precise control: Advanced PLC control system and servo drive technology are adopted to achieve accurate control of temperature, pressure and time, ensure accurate size and uniform wall thickness of each bottle, and improve product qualification rate.

Energy saving and environmental protection: Optimize the heating and cooling system to reduce energy consumption, while equipped with high efficiency filters to keep the production environment clean, in line with the high standard of environmental protection requirements of modern industry.

Easy maintenance: The modular design facilitates quick parts replacement and routine maintenance, reducing downtime and improving overall operational efficiency.

Wide applicability: Adapt to a variety of materials (such as PET, PP, etc.) and different specifications of bottle type production needs, flexible adjustment, to meet the diversified needs of the market.

Application field:

Widely used in beverage bottles, cosmetics bottles, pharmaceutical packaging bottles, edible oil bottles, condiment bottles and other industries, is to improve the level of production automation, enhance the market competitiveness of the ideal choice.

Conclusion:

Jiangsu Xinzi Whale Machinery Manufacturing Group (KIWL) a four blow molding machine, with its excellent performance, efficient production capacity and stable quality assurance, to help customers stand out in the fierce market competition. We are committed to providing customers with a full range of solutions and quality after-sales service, hand in hand to create a better future.