In recent years, the Lun filling machine has undergone significant advancements, reflecting the latest technological innovations. These enhancements are designed to meet the evolving needs of the packaging industry, emphasizing efficiency, precision, and user-friendliness. This article explores the latest design features of Lun filling machines, highlighting their benefits and the impact they have on production processes.

Advancements in Automation

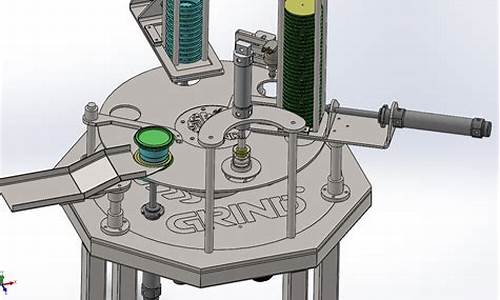

Modern Lun filling machines have embraced automation to streamline the packaging process. The latest models are equipped with advanced control systems that allow for precise adjustments and easy programming. These systems reduce the need for manual intervention, which minimizes errors and increases overall efficiency. Additionally, automated filling machines can handle a variety of container sizes and types, making them versatile tools for different industries.

Automation also enhances the speed of production. With high-speed filling capabilities, these machines can process a larger volume of products in a shorter amount of time. This efficiency not only boosts productivity but also helps in meeting tight production schedules. Furthermore, automation contributes to improved safety, as the risk of human error is significantly reduced.

Enhanced Precision and Accuracy

Precision is a critical factor in filling machine design, and the latest Lun filling machines excel in this area. Advanced sensors and monitoring systems are incorporated to ensure accurate filling volumes and minimize wastage. These machines use cutting-edge technology to measure and dispense liquids or powders with high precision, which is essential for maintaining product quality and consistency.

The integration of real-time monitoring systems allows for continuous quality control. Any deviations from the set parameters can be detected and corrected immediately, preventing faulty products from reaching the market. This level of accuracy is particularly important in industries where compliance with strict regulations is required.

Improved User Experience and Maintenance

User-friendliness is a key aspect of the latest Lun filling machine designs. Modern models feature intuitive interfaces that simplify operation and reduce the learning curve for new users. Touchscreen controls and programmable settings allow operators to easily customize machine functions and monitor performance.

Maintenance has also been streamlined with these new designs. The latest Lun filling machines are built with easy access points for routine maintenance and cleaning. This design reduces downtime and ensures that the machines remain in optimal condition. Additionally, some models include self-diagnostic features that alert operators to potential issues before they become serious problems.

Conclusion

The latest designs of Lun filling machines represent a significant leap forward in technology and efficiency. By incorporating advanced automation, precision technologies, and user-friendly features, these machines are well-equipped to meet the demands of modern production environments. Businesses that invest in these innovative filling machines can expect enhanced productivity, improved accuracy, and a more streamlined operational process. As the industry continues to evolve, the Lun filling machine stands out as a prime example of how technological advancements can drive progress and success in the packaging sector.